Roller Entry Activated: Techniques for Smooth Efficiency

Within the realm of industrial applications, achieving smooth performance is commonly dependent on the standard and consistency of machinery, especially when it comes to roller systems. Such components serve a vital role in ensuring smooth operations, reducing damage, and finally boosting output. Comprehending the details of roller systems is crucial for individuals seeking to optimize their processes and ensure longevity in challenging environments.

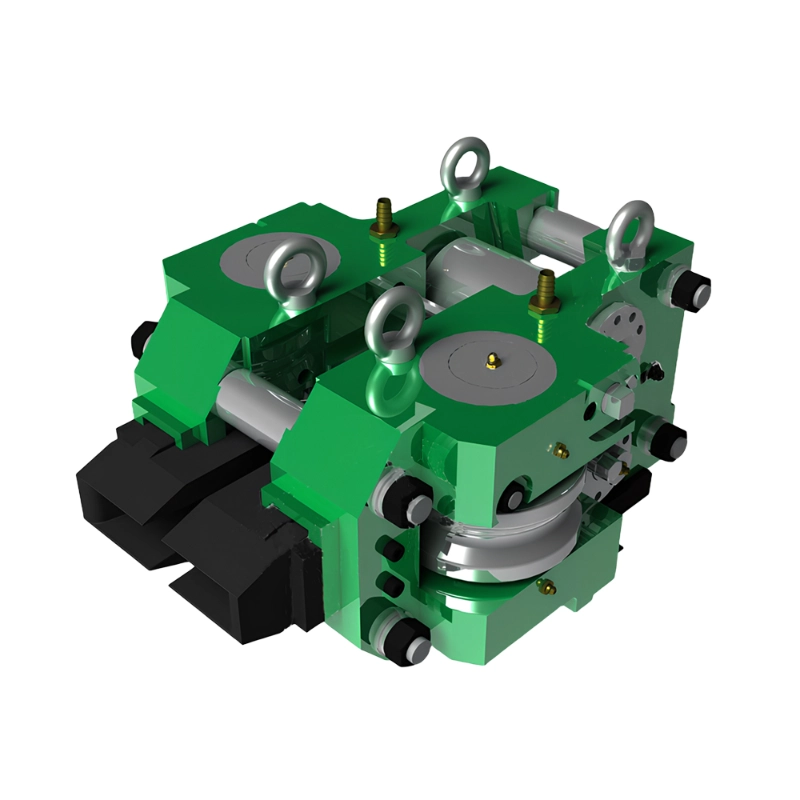

The following guide offers a detailed look at heavy-duty roller entry options that can withstand the rigors of heavy loads and harsh circumstances. Furthermore, we will examine the merits of anti-corrosive roller entries that are engineered to avoid deterioration over the years, guaranteeing stability and reliability. By utilizing the proper methods and choosing fitting substances, you can realize the complete capabilities of roller systems and achieve excellence in performance.

Benefits of High-Strength Rollers Entry Systems

Heavy-duty rollers inlet guides are engineered to tolerate substantial stress and heavy loads, rendering them vital in multiple manufacturing applications. Their durable design ensures that they can handle rigorous operational demands while not compromising efficiency. This durability not only prolongs the lifespan of the systems but also minimizes stoppage caused by wear and tear, enabling for more productive production operations.

Another advantage of high-strength roller entry guides is their ability to enhance precision and consistency during processes. With improved strength, these guides minimize misalignment and allow for accurate control of products as they enter production processes. This precision is crucial for maintaining superior output and reducing the chance of product defects, contributing to overall process excellence.

Additionally, heavy-duty rollers inlet guides often come with elements that make easier easy installation and upkeep. Their durable construction means they are not as susceptible to damage, thus requiring less regular replacements. This aspect not only reduces on material costs but also ensures that manufacturing lines can operate efficiently with minimal disruptions, ultimately resulting to enhanced efficiency and output in industrial operations.

Corrosion Resistance: Key Features and Advantages

Corrosion resistance is a crucial aspect of durable roller entry guides, ensuring their longevity and performance in diverse environments. The materials used in these guides are often treated or coated to withstand severe conditions, including exposure to water, chemicals, and extreme temperatures. This resilience helps preserve functionality over time, reducing the need for regular replacements and lowering maintenance costs for operators.

One of the notable advantages of using corrosion-resistant roller entry guides is their improved reliability. Components that can withstand corrosion are not as prone to fail under challenging operational conditions, which improves overall system performance. Users can trust that their equipment will function smoothly without the disruptions frequently associated with wear and tear caused by corrosion, leading to enhanced efficiency in production processes.

Additionally, the use of corrosion-resistant materials adds to eco-friendly efforts in production and engineering. By prolonging the lifespan of roller entry guides, industries can reduce waste and the ecological consequences associated with producing replacement components. Investing in these innovative guides not only results in better performance but also supports the increasing emphasis on eco-friendly practices in multiple sectors.

Top Guidelines for Implementing Rolling Access Systems

To guarantee optimal efficiency when introducing a rolling entry guide, it is essential to concentrate on the selection of high-strength components that provide durability and reliability. Choosing a robust rolling entry guide not just improves the effectiveness of processes but also minimizes maintenance costs in the long run. Evaluating the specific needs of your project and comprehending the load-bearing limits will help in selecting the most suitable guide that handles demanding environments.

Using a rust-proof roller access system is key for settings exposed to moisture or harsh chemicals. These guides not only improve durability but also guarantee consistent operation without the threat of corrosion. Regular inspections and prompt replacements of any compromised components can further prolong their lifespan, resulting in increased security and reduced downtime.

Training employees on the proper installation and care procedures is essential to optimizing the benefits of rolling access solutions. Ongoing education will enable personnel to identify potential problems early and carry out fixing measures swiftly. Creating a routine care plan along with real-time monitoring can result in optimal efficiency, ensuring that the roller entry system functions seamlessly within its designed use.